Kaoru Ishikawa

Appearance

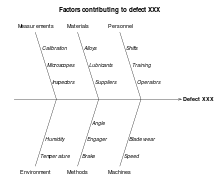

Kaoru Ishikawa (July 13, 1915 - April 16, 1989) was a Japanese organizational theorist, Professor at the Faculty of Engineering at the University of Tokyo, noted for his quality management innovations. He is considered a key figure in the development of quality initiatives in Japan, particularly the quality circle. He is best known outside Japan for the Ishikawa diagram or cause and effect diagram (also known as fishbone diagram) often used in the analysis of industrial processes.

| This article about an engineer, inventor or industrial designer is a stub. You can help out with Wikiquote by expanding it! |

Quotes

[edit]- The fact must be expressed as data, but there is a problem in that the correct data is difficult to catch. So that I always say "When you see the data, doubt it!" "When you see the measurement instrument, doubt it! ... For example, if the methods such as sampling, measurement, testing and chemical analysis methods were incorrect, data ... to measure true characteristics and in an unavoidable case, using statistical sensory test and express them as data.

- Kaoru Ishikawa in: Annual Quality Congress Transactions, (1981), p. 130

- 90 percent of all problems can be solved by using the techniques of data stratification, histograms, and control charts. Among the causes of nonconformance, only one-fifth or less are attributable to the workers.

- Kaoru Ishikawa, as cited in:The Quality Management Journal. Vol. 1 (1993), p. 89

- In management, the first concern of the company is the happiness of people who are connected with it. If the people do not feel happy and cannot be made happy, that company does not deserve to exist... The first order of business is to let the employees have adequate income. Their humanity must be respected, and they must be given an opportunity to enjoy their work and lead a happy life.

- Kaoru Ishikawa, as cited in: Howard S Gitlow (2000), Quality Management Systems: A Practical Guide. p. 3

Quotes about Kaoru Ishikawa

[edit]- Ishikawa, one of the most famous experts of quality control, mentions the following six points as the unique characteristics of Japanese quality control: CWQC, education and training for quality control, quality control circle, nationwide promotion activities 16 valuation system of quality control, and utilization of statistical skills...

- CWQC means at least the following three points. First, everybody in a company participates in quality control activities. Second, every department of the company must participate in the quality control. Quality control can be applied not only for the production line, but also any other department such as planning, sales, personnel management, etc. Sectionalism among departments must be removed. Third, CWQC aims at total quality control of all company activities. It controls not only quality of goods, but also quality of prices, time, and services, etc.

- It is said that quality control starts and ends with education, and everyone in a company must be educated in CWCQ. This is partly because quality control is based on statistical analysis of data, and requires that everyone has a basic knowledge of statistics. However, a more important reason for education and training is that quality control is one of the management philosophies to change the quality of the company itself, and therefore, systematic and repeated education is essential to understand and implement this new philosophy.

- Ken Inove (1985), Education & Training of Industrial Manpower in Japan. p. 52

- There is so much to be learned by studying how Dr. Ishikawa managed to accomplish so much during a single lifetime. In my observation, he did so by applying his natural gifts in an exemplary way. He was dedicated to serving society rather than serving himself. His manner was modest, and this elicited the cooperation of others. He followed his own teachings by securing facts and subjecting them to rigorous analysis. He was completely sincere, and as a result was trusted completely.

- Joseph M. Juran (1989), cited in: Russell T. Westcott, "Leave A Legacy". Quality Progress. December 2009. p. 63.

- [ Total Quality Management (TQM) is] a term first used to describe a management approach to quality improvement. Since then, TQM has taken on many meanings. Simply put, it is a management approach to long-term success through customer satisfaction. TQM is based on all members of an organization participating in improving processes, products, services and the culture in which they work. The methods for implementing this approach are found in the teachings of such quality leaders as Philip B. Crosby, W. Edwards Deming, Armand V. Feigenbaum, Kaoru Ishikawa and Joseph M. Juran.

- American Society for Quality, "Quality Glossary," at asq.org. Accessed 08.2016